Small-Shop Service,Big-Shop Results

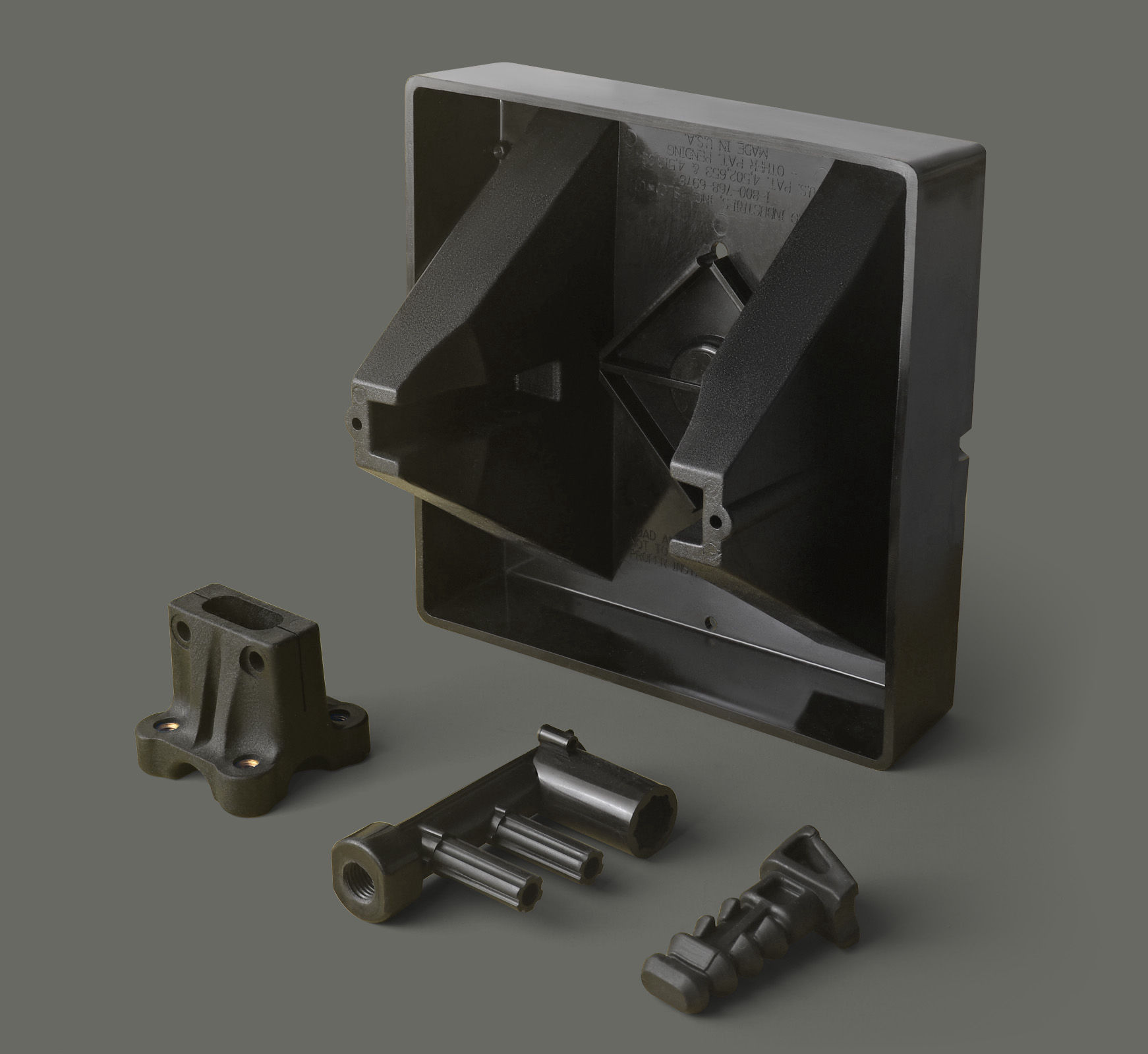

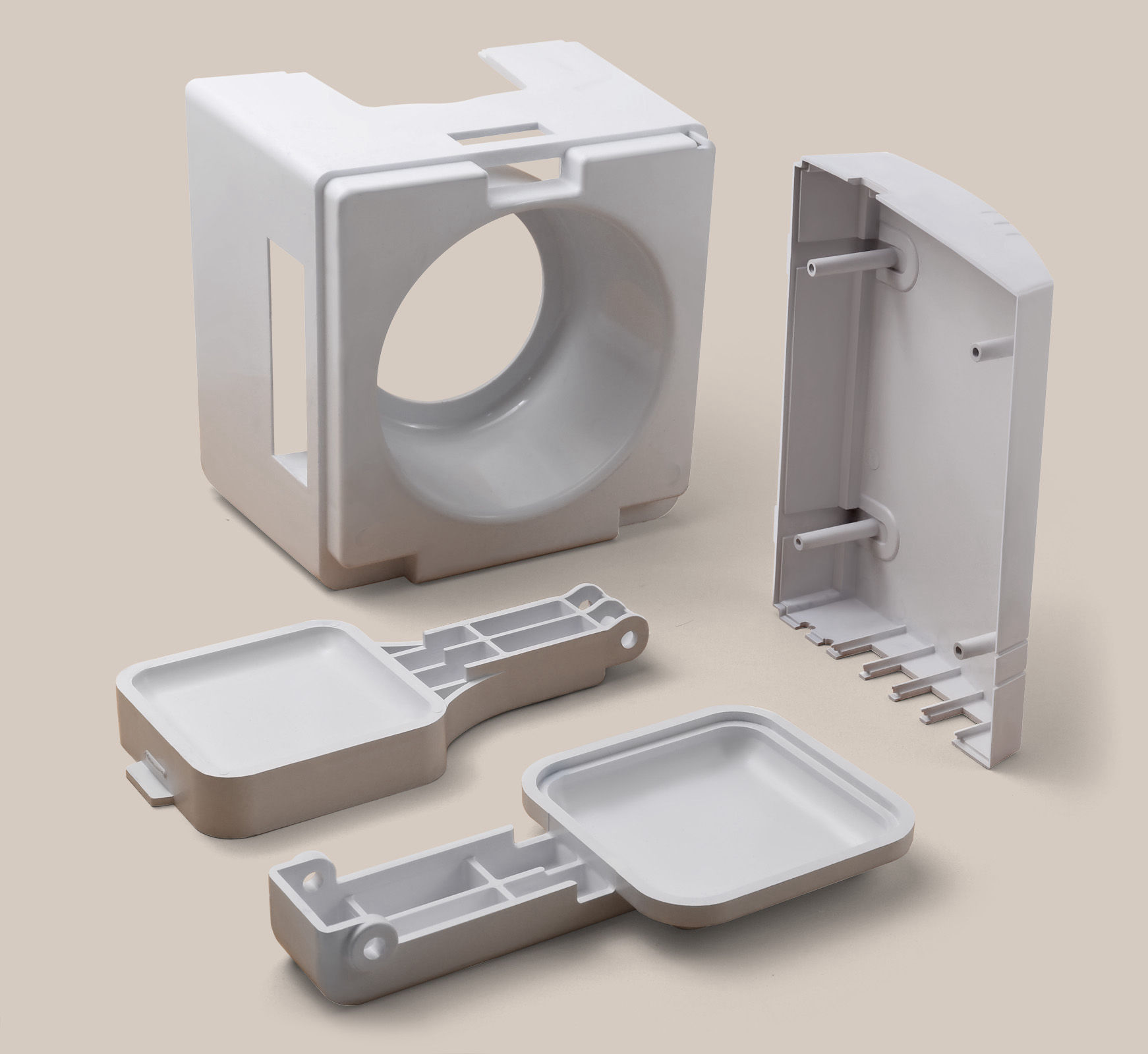

Maximum Machine produces precision machined and injection molded parts. We turn your ideas into reality by creating molds and producing finished parts all under one roof. We provide professional service with a "small shop" atmosphere. We are dedicated to our customers and their deadlines.